Industrial PLC Center

Cooperation with Germany, the United States, the United States, etc., high-energy efficient laser equipment developed, and a number of technologies are in domestic leading position, especially the metal laser cutting technique, in terms of Asia, in terms of cutting thickness and cutting speed.

Wave length range 1070-1090 nm, beam quality Temoo (M2 <1.4), more than 100,000 hours of pump secondary tube life, maintenance operation, single-mode fiber transmission, better spot mode and cutting efficiency, professional application to metal Cut.

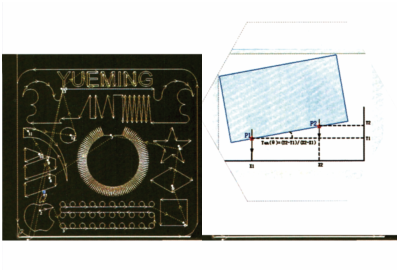

Professional thin steel cutting special software

1. Adaptive trajectory smooth algorithm, the cutting path is automatically optimized.

2. Automated landwork function.

3. The BEZier curve transition algorithm is used to achieve high efficiency turning, avoiding the phenomenon of burning angles in thermal processing.

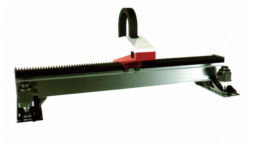

Dual motor double gear synchronous drive system, with high strength aluminum alloy beam, maximum acceleration can reach 1-2g, achieving high efficiency cutting, more processing efficiency, greatly reduced gas consumption.

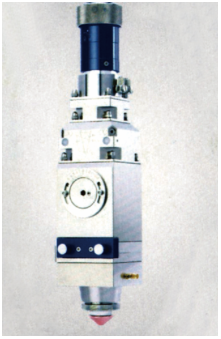

The speed position double closed ring algorithm is used to control the laser cutting capacitor with the moving head, with a higher dynamic response accuracy, support the frog jumping, and achieve high speed follow.

France Schneider Electric high-inertia servo system, with the highest drive responsiveness of the same industry, greatly shortening the tuning time, high-speed implementation of acceleration, helps to improve the stability of the machine.